International Women's Day, Spring happenings, and the table saw

Happy International Women’s Day to all! I’m grateful to have learned carpentry in the company of so many remarkable women and non-binary folks over the past few years at Hammerstone. Without this school, I’m not sure I would have envisioned myself learning the skills that I now possess. The field of carpentry is slowly changing, but the share of women is still extremely low: from 2020 to 2023 this increased from 3.2% to 5.5%.

Being the only woman on the job site is still the dominant reality for most. This can result in a phenomenon called stereotype threat: social psychology’s term for the fear of confirming stereotypes about oneself. It’s the feeling of being scared of being the woman who of course can’t hit the nail with the hammer. Research has shown that stereotype threat can lead to a downward spiral, which many of us are probably familiar with in some context:

One of the main things I appreciate about Hammerstone is that our affinity spaces allow for something different. In the absence of stereotype threat, the spiral looks more like this:

When self-critical distraction is lessened, we begin to see openness, curiosity, and trust in our capability to learn. There are still plenty of mistakes and frustrations, but it’s easier to move past them and return to the task at hand. This testimonial from a student last month said it well:

“Being able to leave the pressure of

‘Will I be understood or taken seriously?’

at the door was priceless.

It freed me up to just be.”

Pretty amazing that simply being together as women can create this shift. I hope you all did something special to celebrate yourselves or the women in your life. And if not, Women’s History Month is all of March, so don’t fret.

Happy Hammering,

Kimberly and the Hammerstone Team

Table Saw

If there's one tool that women are frequently told not to use, it's this one. Statistically, the table saw is the most dangerous carpentry tool. It's also one of the most versatile. Comfort in using this tool opens up world of possibility, in both rough carpentry and fine woodworking.

How does a table saw work?

Wood is fed through a table saw -- the user brings the workpiece to the saw and pushes it past the circular cutting blade. The table saw fence restricts the movement of the workpiece to ensure a straight cut. The blade height and angle are both adjustable.

Why use one?

The table saw excels at performing precise, repetitive cuts. It's often the best tool to cut along the length of a piece of wood, e.g. ripping a 2x4 into two 2x2s. When I say the table saw is versatile, what I mean is that it can be set up in countless ways for different tasks: tapers, dovetail joints, box joints, tenons... just Google "table saw jig" and you'll see what I'm talking about.

Can you guess what these jigs are used for?

Answers at the bottom of the newsletter.

Types of Table Saws

1. Jobsite Saw:

Benchtop saw (as in, you place it atop a bench or stand) you can chuck in the back of a pickup truck, or tuck away when not in use. A great option for those with small workshops.

2. Contractor Saw:

Semi-stationary saw attached to its own 4-legged stand. More stability, better fence options, and a larger work area. Usually on casters, so it can be moved out of the way if needed.

3. Cabinet Saw:

Professional saw with a heavy, stable base. Precise and powerful. Usually has a cast iron top and excellent adjustability controls. Designed to have a permanent location in the shop.

Table Saw Fundamentals:

saturday April 26th

Every spring we offer a one-day Table Saw Fundamentals course to teach the basics of safely using this tool. The project for the class is an apple crate.

All students get extensive practice with the saw during this class. We try to give students as much time on the saw as possible so that they can get used to it, both in terms of dampening the feeling of fear that naturally arises, and learning the body mechanics of proper technique. Both take repetition.

This class is perfect for anyone who wants to develop confidence in safely using the table saw: we go over rip cuts, cross cuts, using a crosscut sled, using a push stick, and most importantly, how to prevent kickback during all of these actions.

I took Table Saw Fundamentals in 2021, and now use my table saw on a daily basis when I'm in the shop.

Here's a project that was mostly table saw work: 22 solar dehydrator frames I built for an herb farmer.

I used the saw to cut half-lap joints in 2x6 material then rip the boards into smaller pieces. Can you spot my apple crate from the class?

If you've been on the fence about it, sign up today :)

Goodbye Venus,

Hello Spring!

She's really gone! Venus, the house we built in our tiny house course series last year, was transported to North Carolina last Wednesday.

Spring is for woodworking! We just finished up an excellent Kumiko class and we have Parquetry coming up this week. 1 spot left in this class!

March 14-15: Parquetry Basics

Students are gearing up to build their raised beds and spring garden projects. Our next 2-Day Basic Carpentry Skills on April 12-13 is full!

We still have room in our May and June classes - save your spot now then spend your summer building things!

2-Day Basic Carpentry Skills

April 12-13 *full, waitlist only*

Tiny House Courses

Venus is gone just in time to make way for our new tiny house build! Join us this season to get some sunshine, make new carpentry friends, and experience the joy and satisfaction of standing back and saying,

"I built that."

Rough Framing - Build a Tiny House

Tiny House Dry-In Sheathing and Windows

Intro to Building Science and Insulation

youth scholarships

Thanks for helping us spread the word! We still have a few of these available for youth (16-21) in Tompkins County, so apply today. First come, first served!

The transition from gray to green has begun!

Until next time,

Hammer On!

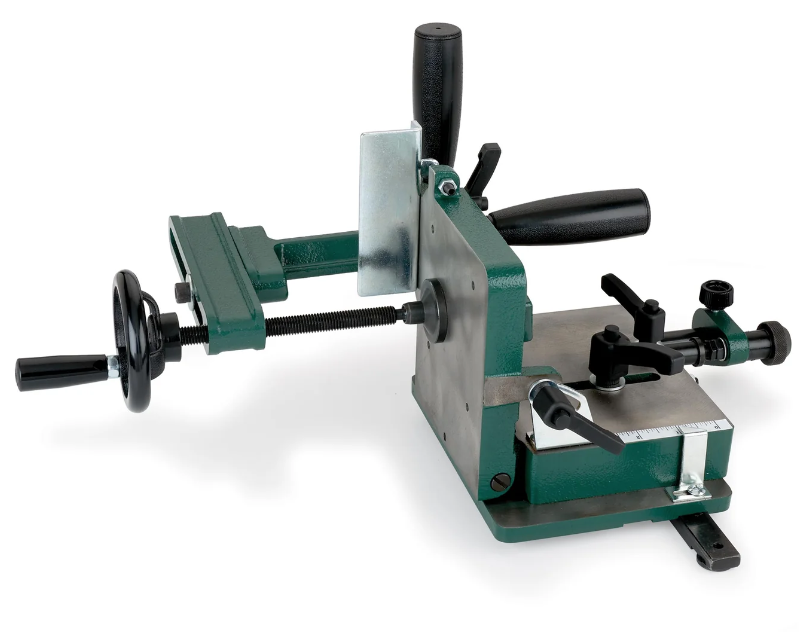

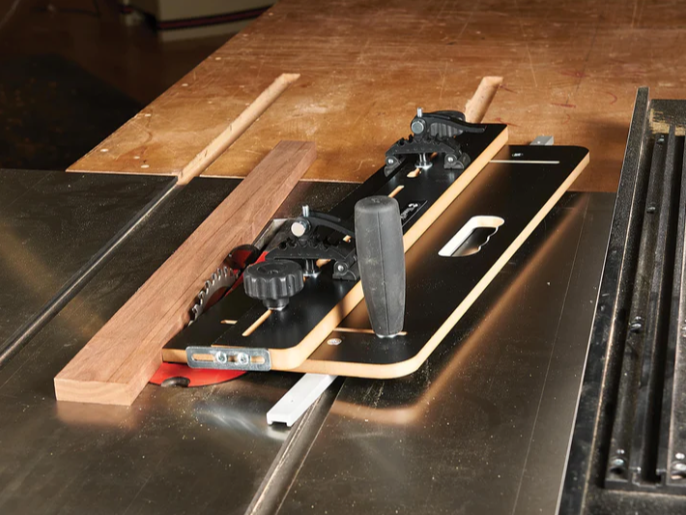

Mystery Jig Answers

On the left is a tenoning jig that safely holds wood vertically to cut straight, angled, or mitered tenons. On the right is a taper jig used to cut accurate and repeatable tapers. Both of these can be bought from Woodcraft.com or built in the shop!